Managing MEWPs During the Festive Period: Safety, Storage and Cost Savings

This guide explains how to correctly store MEWPs over Christmas and winter, how to reduce downtime, and how to take advantage of cost-saving measures available during the holiday period.

Hiring a Mobile Elevating Work Platform (MEWP) gives you critical on-site access and efficiency. However, over the festive period many construction sites and industrial operations shut down for days or weeks. If your MEWP is left unused during this time, the way you shut down, store and secure it will directly influence:

-

Safety

-

Operational readiness when you return

-

Costs associated with hire and transport

-

Battery efficiency and lifespan

-

Risk of theft or unauthorised use

This guide explains how to correctly store MEWPs over Christmas and winter, how to reduce downtime, and how to take advantage of cost-saving measures available during the holiday period.

Security and Theft Prevention With SkySentry™ Telematics

One of the biggest risks during quiet site periods is theft or unauthorised machine use. To help protect your MEWP, SkySentry™ Telematics can be activated for your hire.

Once enabled, the system restricts machine access and ensures equipment remains secure even when your team is off site. The process is simple:

1. Contact the hire desk to request activation

2. Receive a PIN number for authorised operators

3. The system can be set up remotely if your machine is already on site

When shutting down for Christmas, your operator isolates the machine by removing the key. When they return, they simply re-enter the PIN and use the key as normal.

For machines on hire now or ordered before the end of 2025, SkySentry™ is available at no additional cost.

If you are hiring multiple machines or operating a busy site, enabling telematics across your MEWPs will significantly reduce risk and ensure complete peace of mind.

Hire charge suspension over Christmas

Moving equipment off hire during the holidays is not always convenient. You may face additional transport costs and delays when restarting work in January.

To avoid this, hire costs are suspended for all Christmas bank holiday days, meaning:

-

No off-hire is required

-

You avoid transport fees and unnecessary logistics

-

Your MEWP stays on site and ready to use immediately after the festive break

-

You minimise emissions (each 40-mile round trip can produce around 40kg of CO₂)

This approach enables both cost reductions and environmental benefits, while ensuring your machine is ready to start work on day one in January.

How to Avoid Unwanted Downtime When Returning to Site

After a Christmas or winter shutdown, many MEWP users experience operational downtime because equipment has been incorrectly powered down or exposed to adverse weather.

To prevent delays, follow these simple operator shutdown practices.

How to correctly shut down MEWPs after use

Boom Lifts

Use the following steps to correctly shut down and secure your boom lifts at the end of the working day.

1. Select a safe parking location - firm level surface, clear of obstruction and traffic.

2. Retract and lower the boom to the stowed position.

3. Rotate the turntable so that the boom is between the non-steer wheels.

4. Turn the key switch to the off position and remove the key to secure from unauthorised use.

Scissor Lifts

Follow the steps below to fully power down and secure your scissor lifts when work is finished.

1. Select a safe parking location - firm level surface, clear of obstruction and traffic.

2. Lower the platform.

3. Turn the key switch to the off position and remove the key to secure from unauthorised use.

4. Charge the batteries.

Emergency Stop Button Positioning

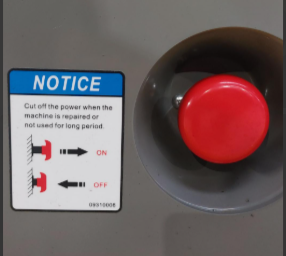

Every MEWP has an emergency stop button at both the platform and ground controls. During winter, incorrect stop-button positioning can cause the internal contacts to freeze, preventing machine start-up the next day.

At the end of each shift:

-

Leave both emergency stop buttons in the OUT (not depressed) position

-

Switch the machine off using the ground key switch

-

Remove the key to secure the machine

Leaving the stop button depressed traps moisture, and in sub-zero temperatures the internal contacts can freeze shut, resulting in non-operation the following morning.

Gap is closed – the stop button has been depressed. During cold periods the contacts inside will freeze shut and cause the machine not to operate the following morning.

.png)

Gap is open – the stop button has NOT been depressed. During cold periods this will stop a potential issue.

Gap is closed – the stop button has been depressed. During cold periods the contacts inside will freeze shut and cause the machine not to operate the following morning.

Gap is open and showing green (image) – the stop button has NOT been depressed. During cold periods this will stop a potential issue.

Key switches at the ground controls

Key switches located at the ground control panel are your primary isolation method. When shutting the machine down:

-

Turn the key switch to OFF or zero

-

Remove the key to secure the machine from unauthorised access

Battery isolators on electric and hybrid MEWPs

Certain electric and hybrid models are fitted with battery isolator switches that disconnect the battery pack from the machine. Using the isolator:

-

Prevents any additional power draw overnight

-

Improves battery lifespan

-

Maximises machine charge for operators returning after a shutdown

Always isolate the battery at the end of daily use if the machine will sit idle.

Key tips for MEWPs in cold weather

Cold weather has a direct impact on performance, charging efficiency and hydraulic operation. These measures will help reduce downtime and maintain performance:

1. Leave all stop buttons in the on position and disable the machine by turning the key switch to the off position and removing the key.

2. Leave the machine either inside a building if possible or under cover to prevent rain freezing on the machine/controls.

3. If you cannot leave the machine inside or under cover then try to cover the control box with a cover to prevent frost build up.

4. Where possible on a scissor lift, remove the top control box and keep in a dry area inside.

5. Always put the machine on charge overnight and then check the battery water levels before use where appropriate on an electric or hybrid machine.

6. If using a diesel or hybrid machine, keep the fuel tank topped up and use clean filling containers.

7. Perform your daily checks on engine oil and water levels daily and prior to use.

8. Always use the glow plugs when starting a diesel or hybrid engine and allow time for the glow plugs to heat up – DO NOT continue to try to start if the engine does not fire up straight away as you will simply kill the battery. If it does not start straight away, use the glow plugs for a further 30-45 seconds before trying to start the engine.

9. Once running, allow the engine to run for at least 15 minutes before operating as the hydraulic oil may be cold and will slow down the machine operation until it gets to working temperature.

Charging guidance for electric & hybrid MEWPs

Correct charging practices maximise run time, reduce battery degradation and improve operator efficiency.

If your team uses electric or hybrid MEWPs regularly, share your charging procedures across site and ensure:

-

Overnight charging is standard practice

-

Batteries are not run completely flat

-

Water levels are checked as per manufacturer guidance

-

Operators avoid short, frequent incomplete charges

For full operational guidance, access our golden rules for MEWP charging resources:

Managing MEWPs effectively over the festive period reduces costs, eliminates downtime, improves security and prolongs the lifespan of both batteries and hydraulic systems. With correct shutdown, weather protection and charging habits, your operators will be able to restart work in January without delay.

If you are hiring MEWPs over the Christmas period and would like:

-

SkySentry™ Telematics activated

-

Guidance on winter machine storage

-

Charging resources for your site teams

-

Clarification on Christmas hire charge suspension

Get in touch with your account manager or hire desk.

We wish you a safe shutdown period, a Merry Christmas and a productive start to 2026.