Scissor Lift Hire

Providing access up to 33.5m, our wide range of scissor lifts offer versatile access both indoors and outdoors, with electric, bi-fuel, hybrid, gas and diesel options available.

Filter

Working height

Environment

Showing 1-24 of 87 results

-

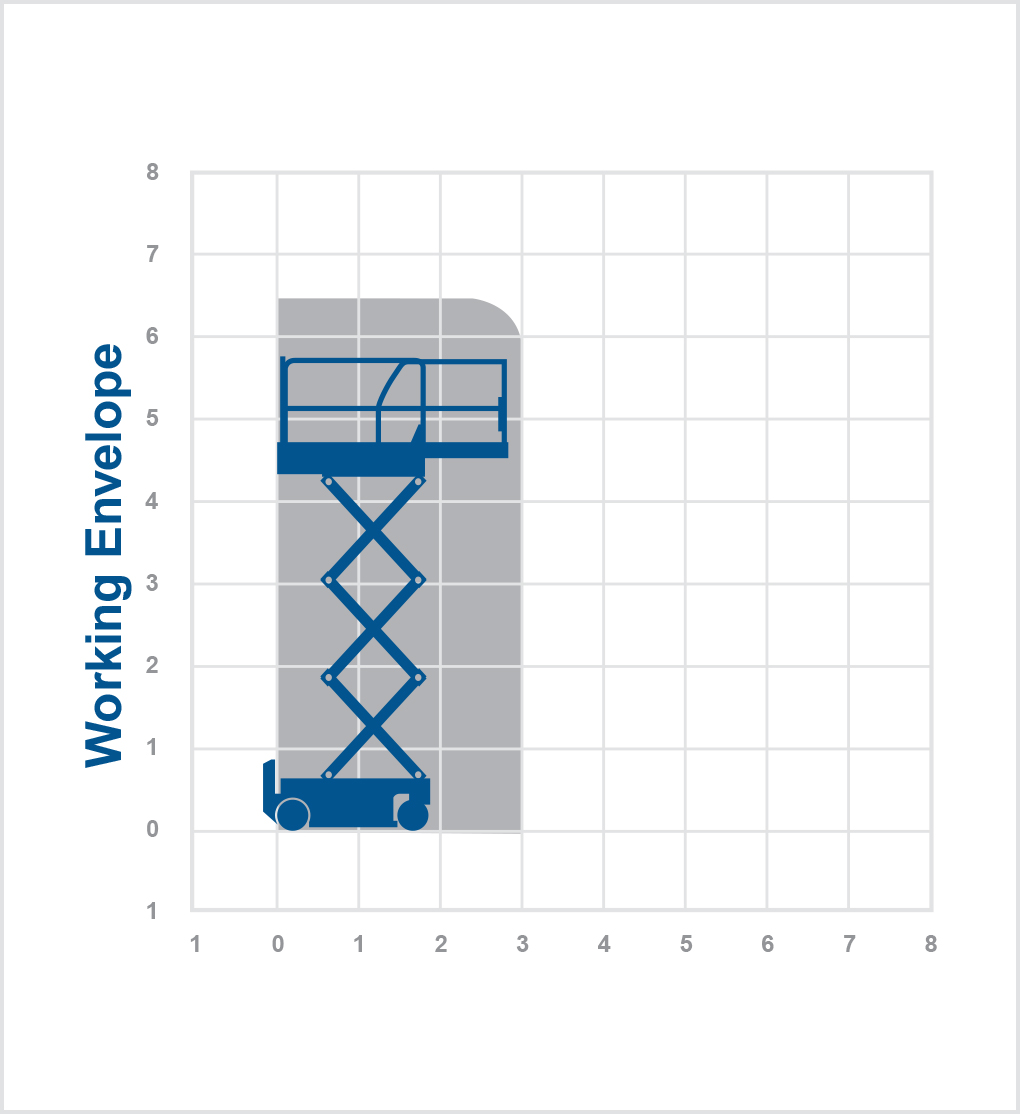

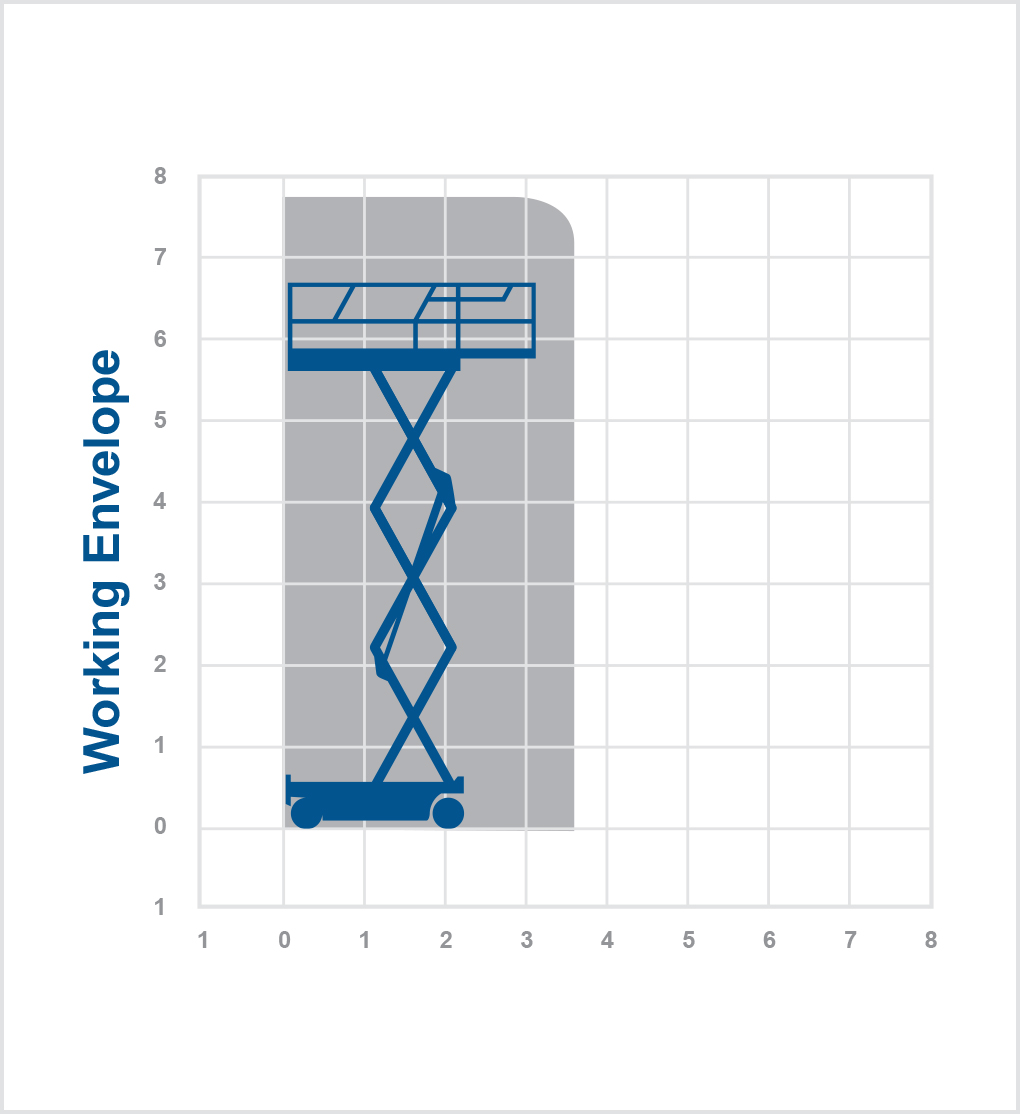

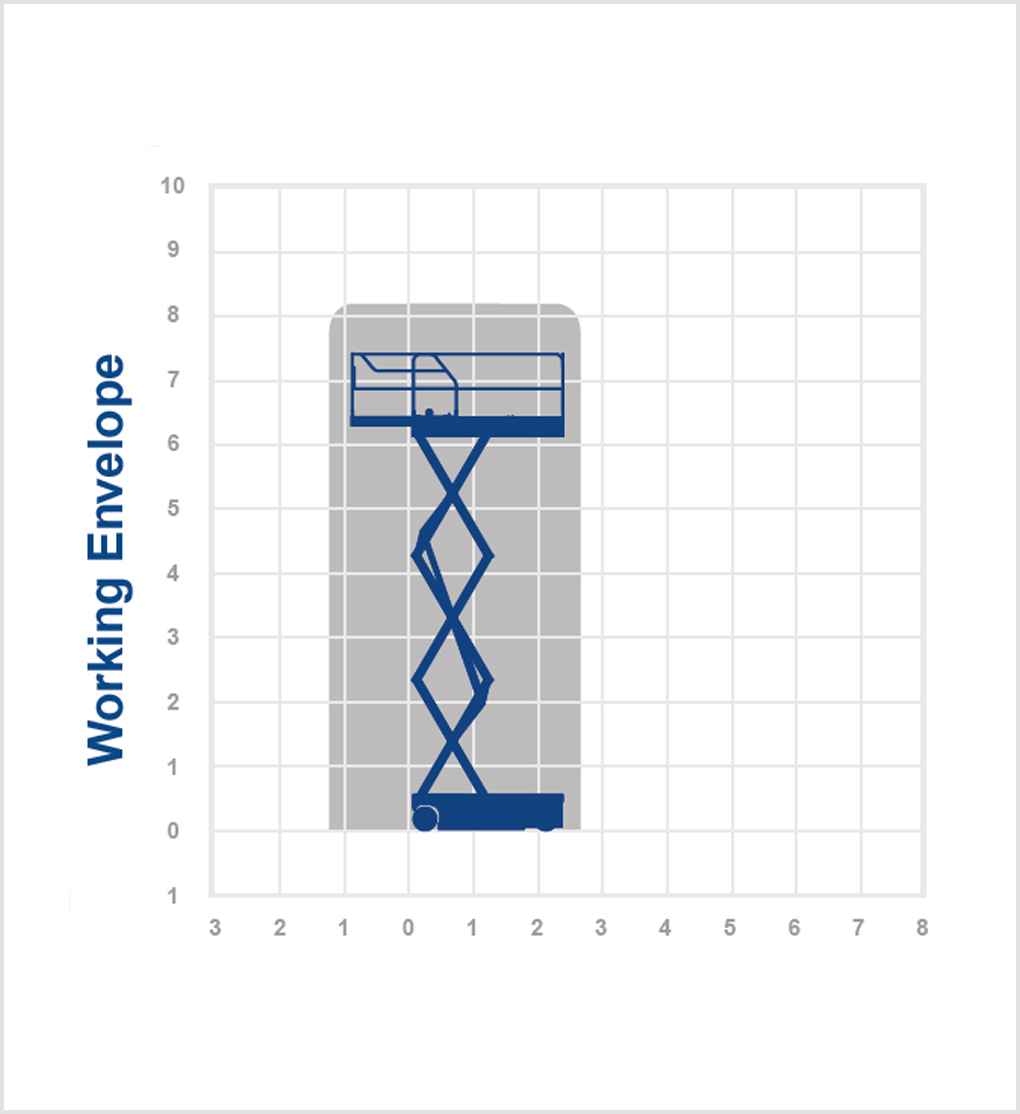

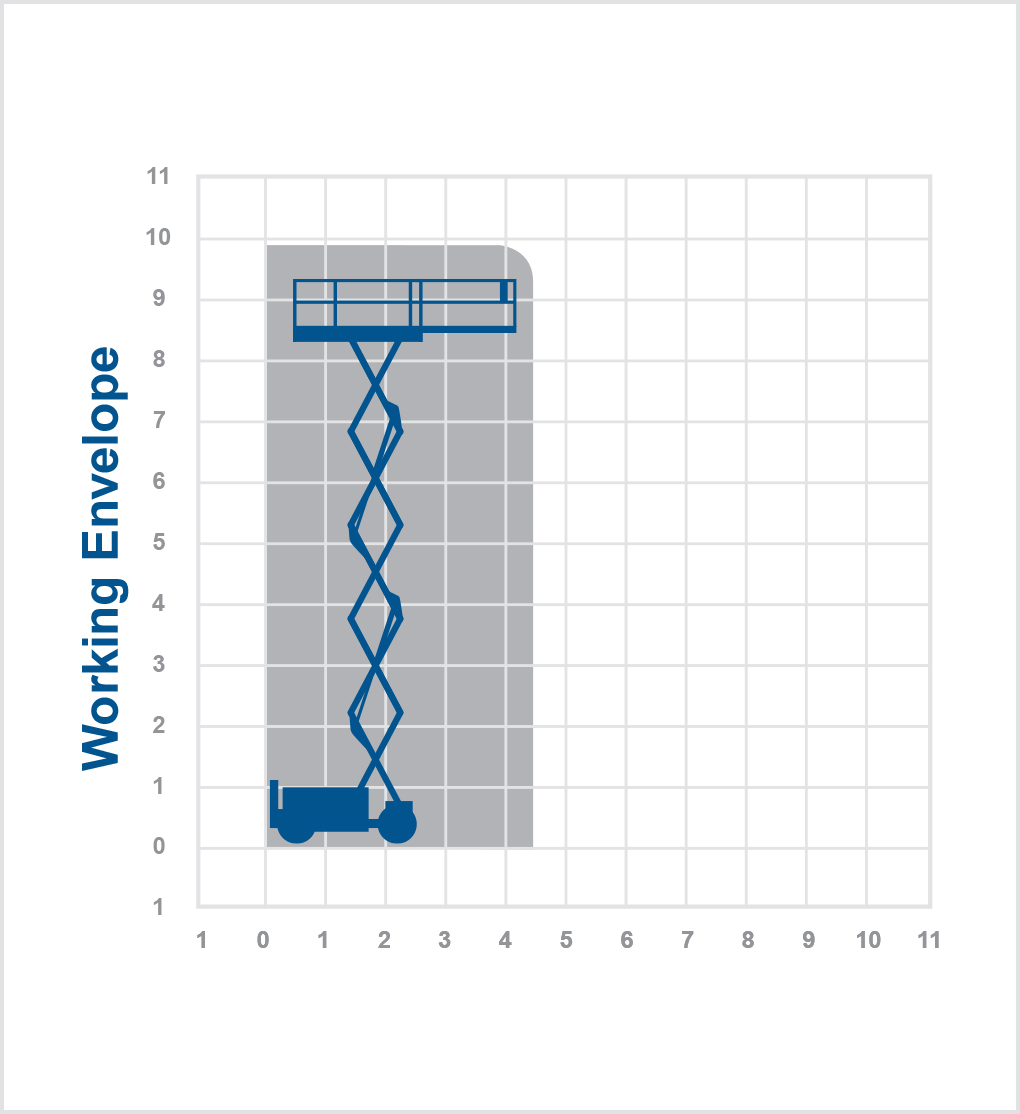

GS1532

Working height: 6.4m Safe working load: 272kg Platform/deck size: 1.63m x 0.75m Platform height: 4.4m -

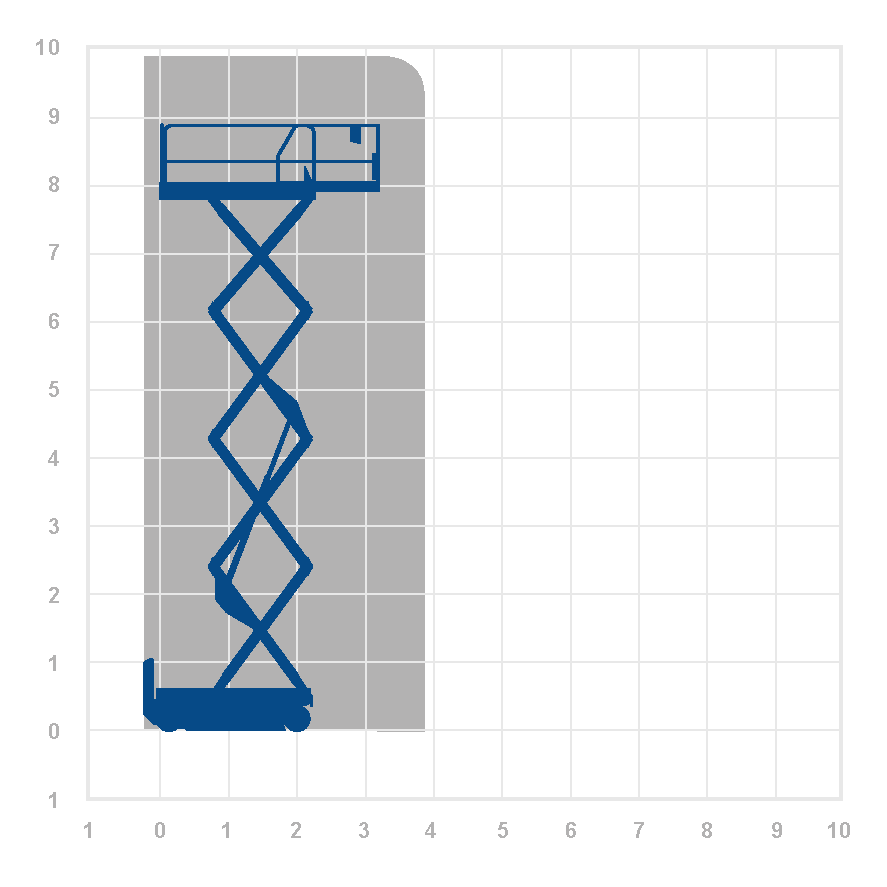

SJ3215

Working height: 6.57m Safe working load: 272kg Platform/deck size: 1.55 x 0.66m Closed length: 1.8m -

SJ3219

Working height: 7.65m Max safe working load: 227kg Platform/deck size: 0.65 x 1.54m Platform length (deck extended): 2.46m -

0807AC

Working height: 7.8m Safe working load: 230kg Platform/deck size: 1.67m x 0.74m Closed width: 0.76m -

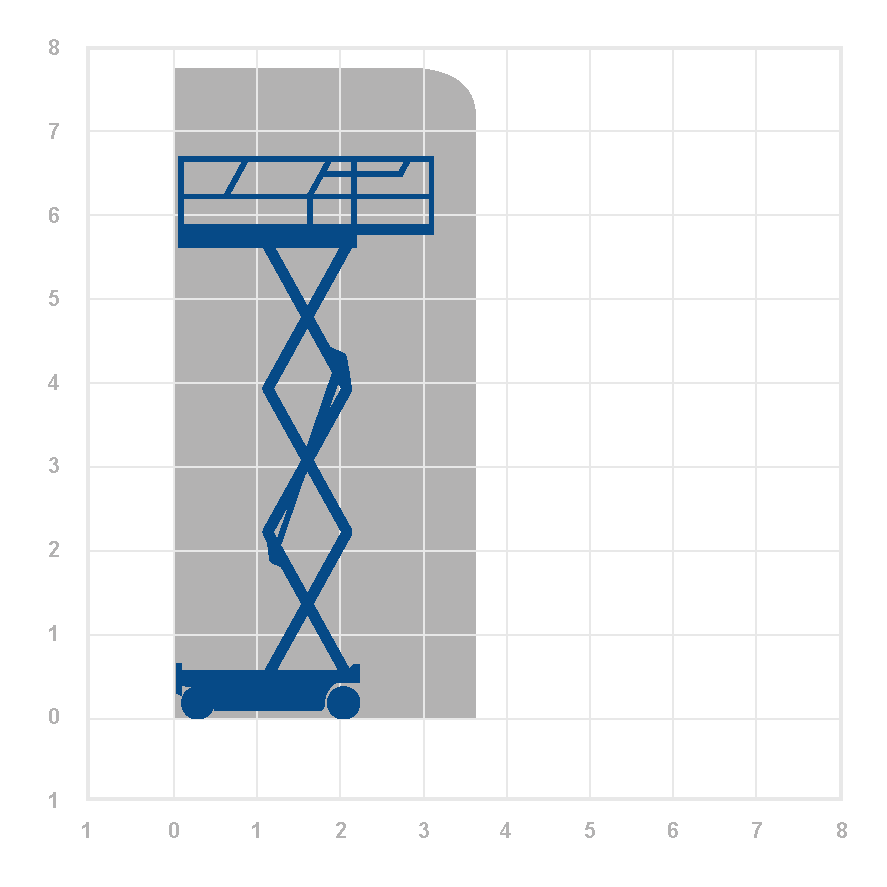

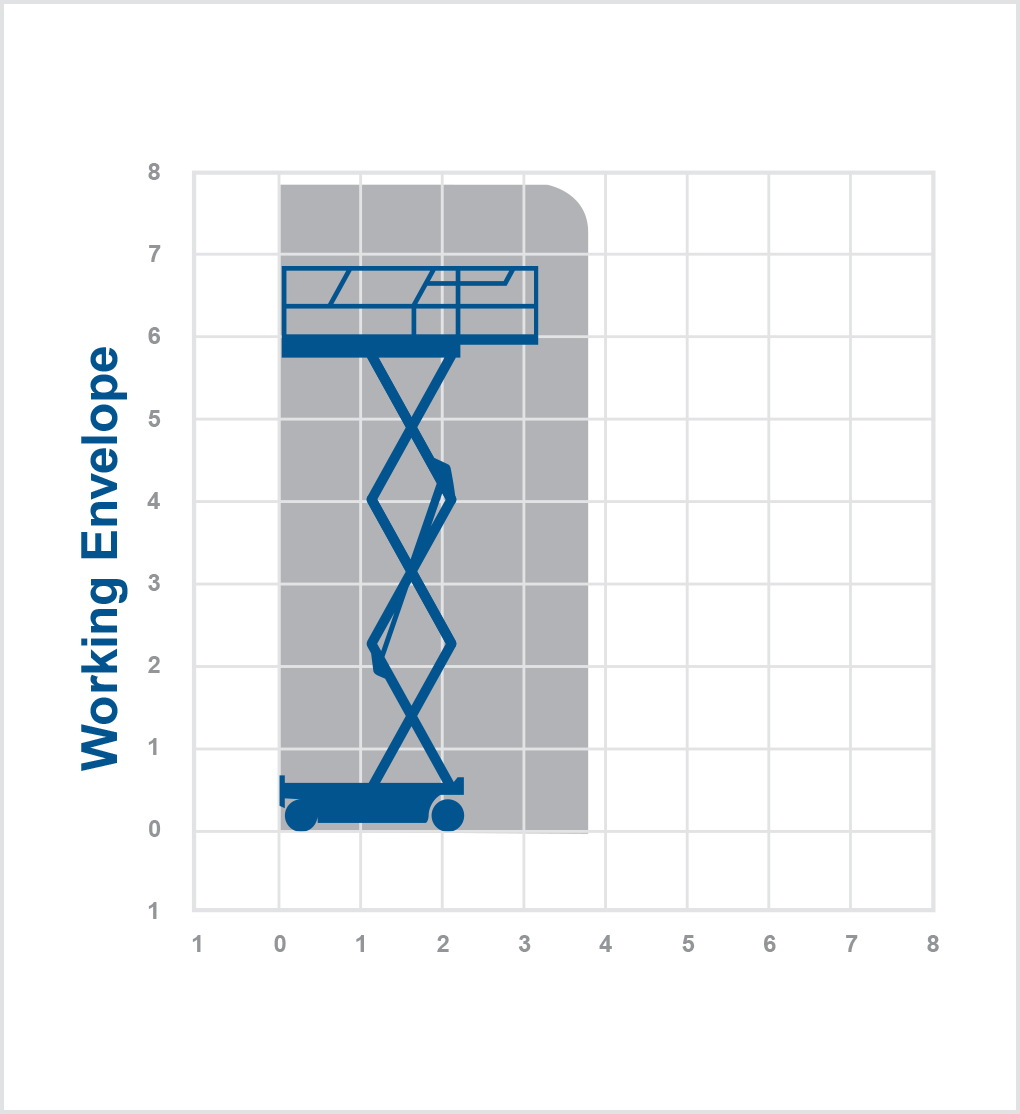

GS1932

Working height: 7.8m Safe working load: 227kg Platform/deck size: 1.64m x 0.75m Platform height: 5.8m -

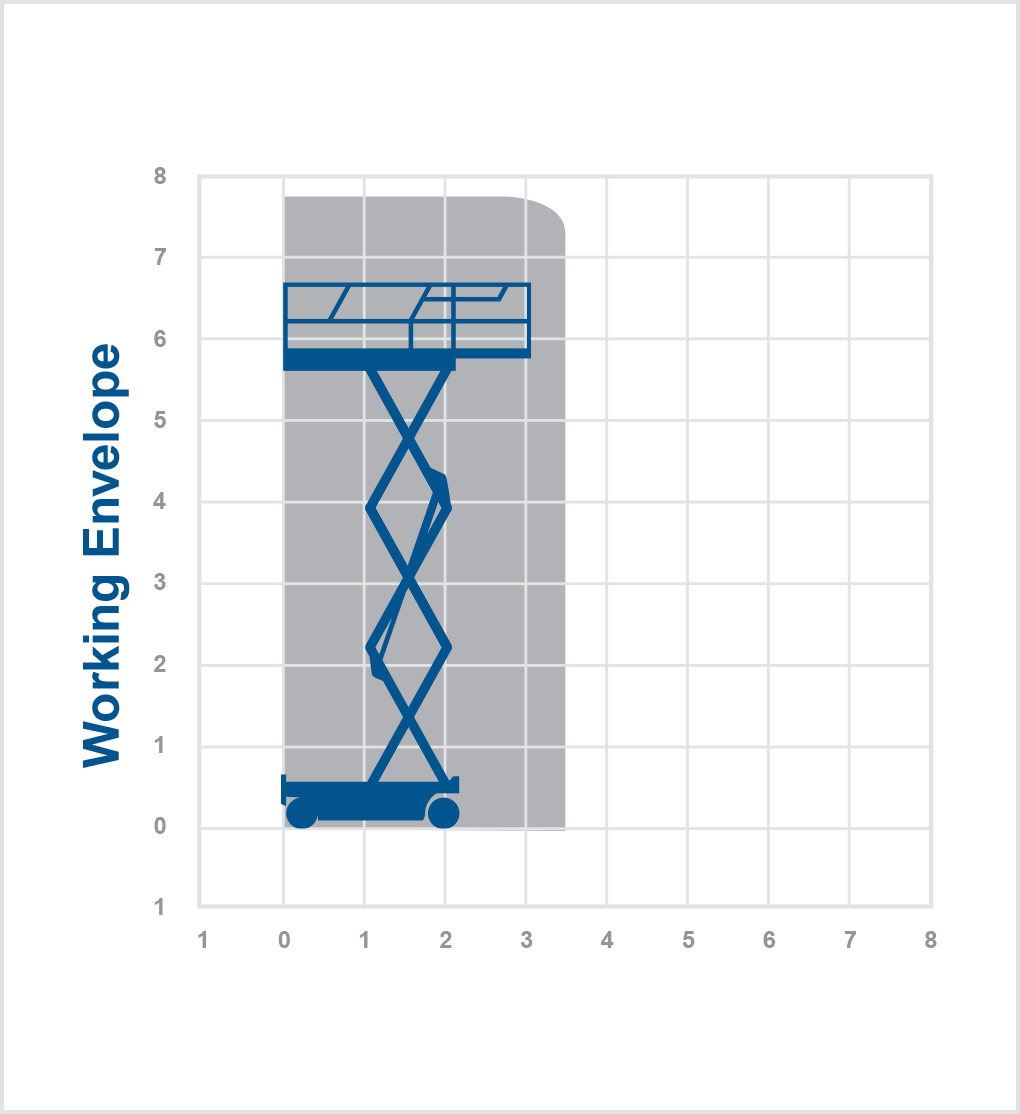

3219

Working height: 7.8m Safe working load: 227kg Platform/deck size: 1.57m x 0.66m Platform height: 5.8m -

GS20

Working height: 7.92m Safe working load: 363kg Platform/deck size: 2.26m x 0.81m Platform height: 5.92m -

0808AC

Working height: 8.0m Safe working load: 380kg Platform/deck size: 2.27m x 0.81m Closed width: 0.83m -

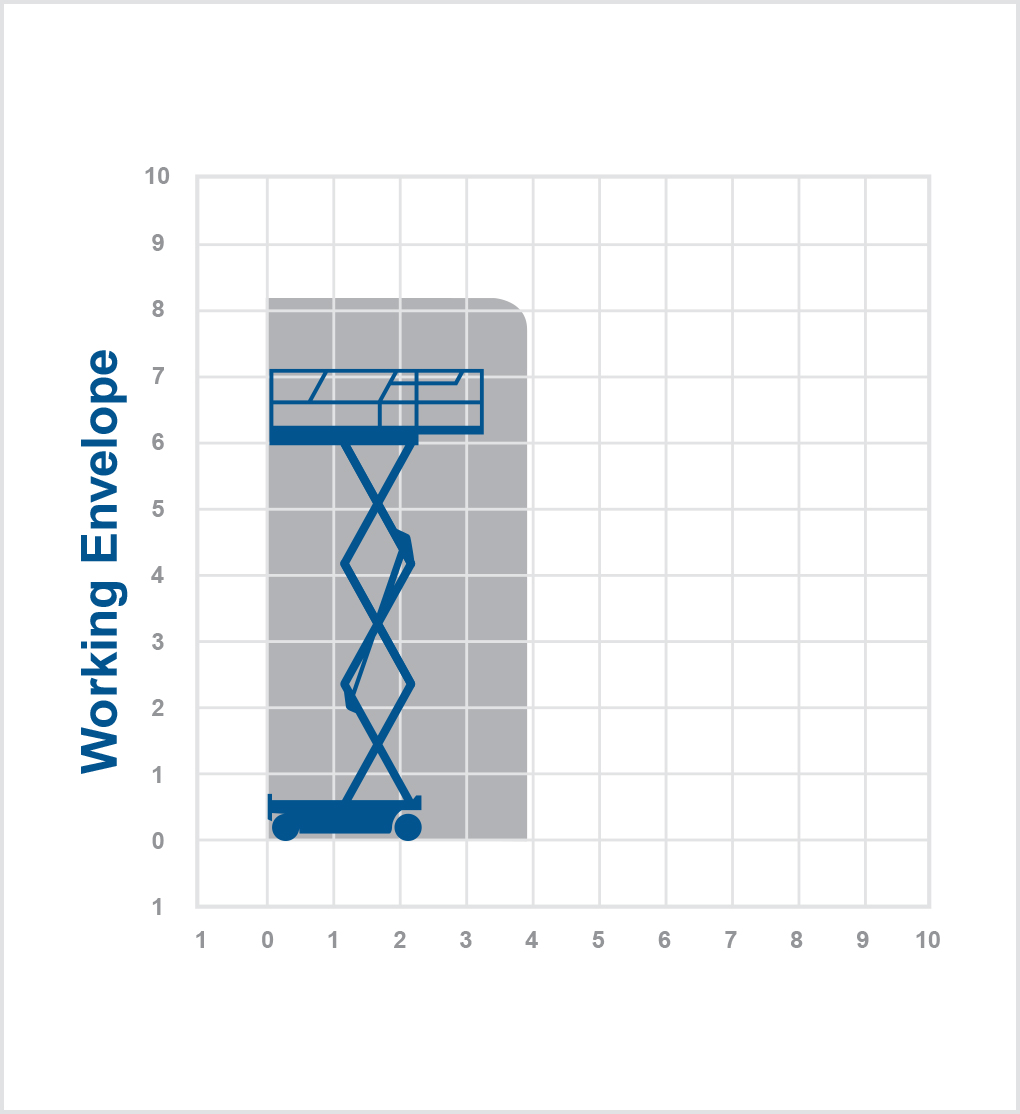

3220

Working height: 8.1m Safe working load: 408kg Platform/deck size: 2.13m x 0.71m Platform height: 6.1m -

SJ3220

Working height: 8.1m Safe working load: 408kg Platform size: 0.7m x 2.10m Platform length (deck extended): 3.02m -

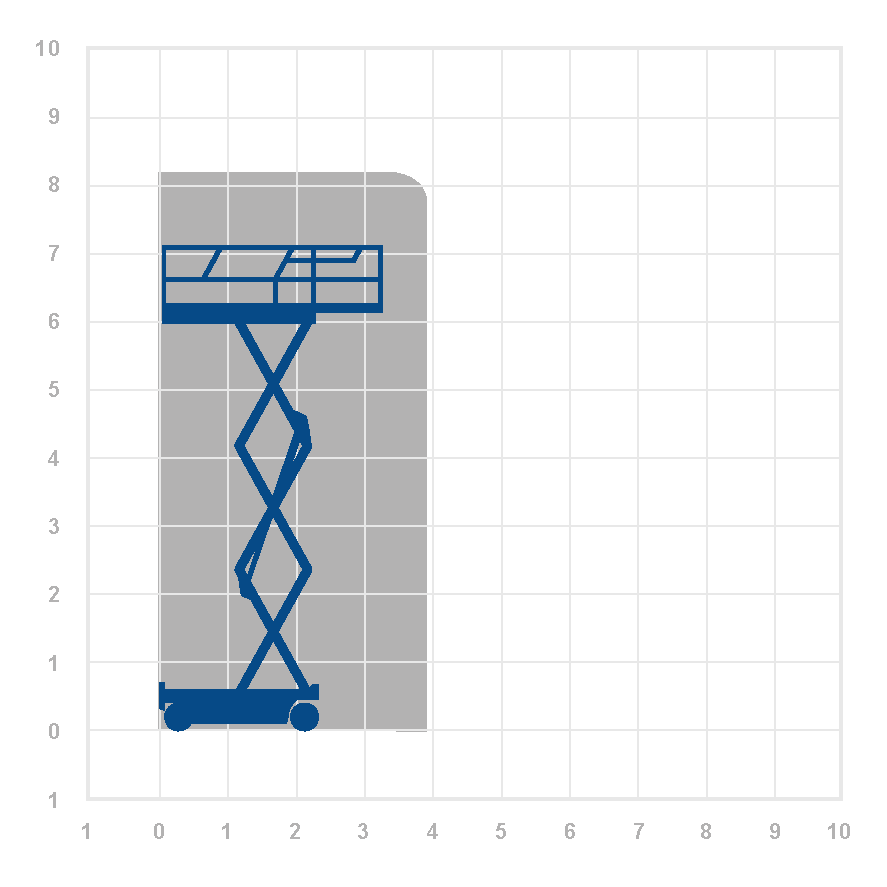

COM8

Working height: 8.2m Safe working load: 350kg Platform/deck size: 2.31m x 0.81m Platform height: 6.2m -

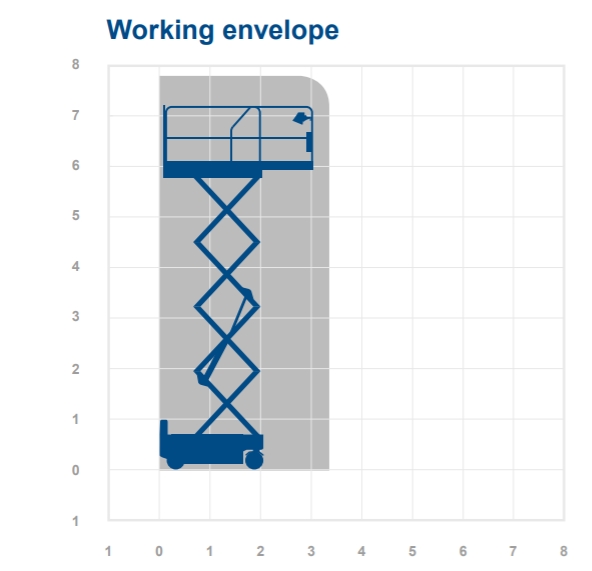

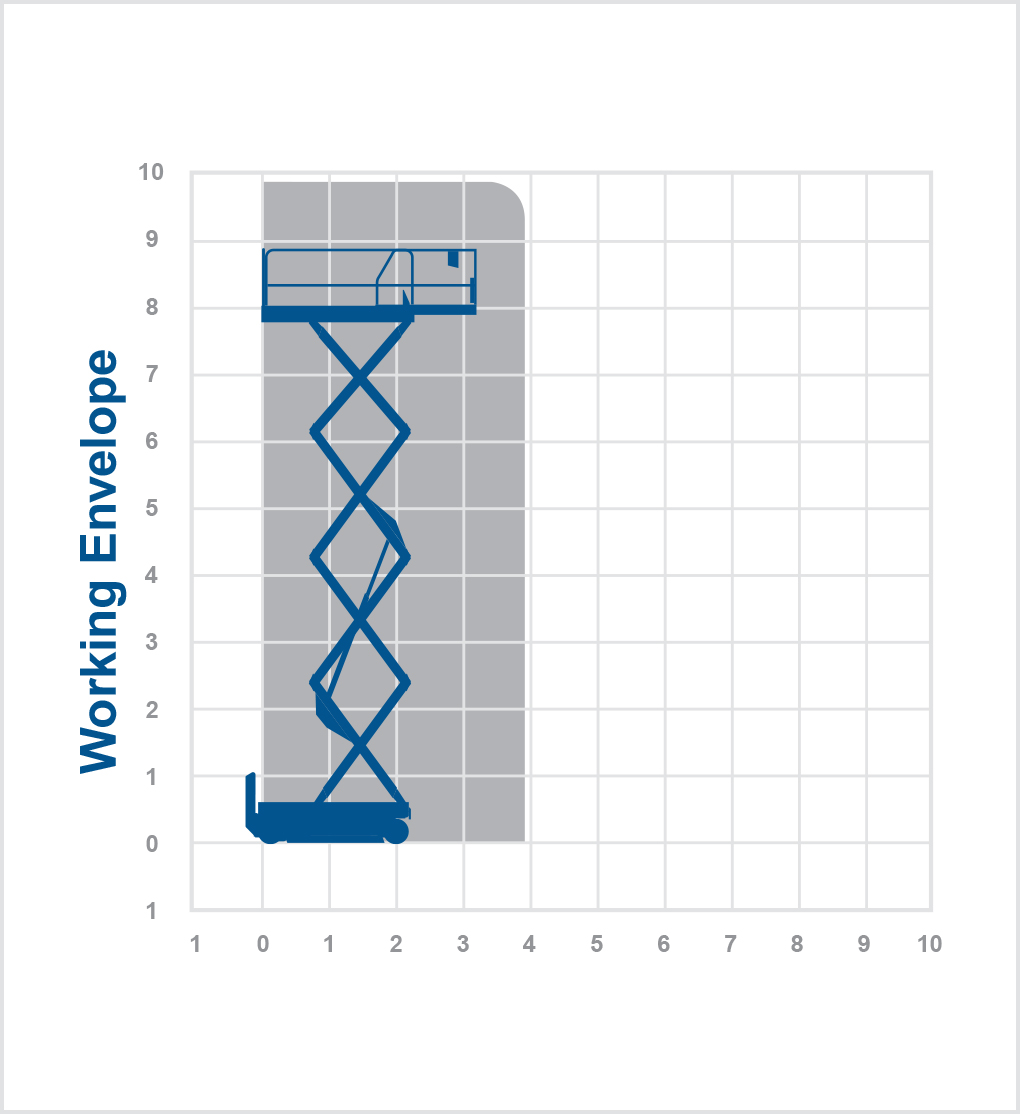

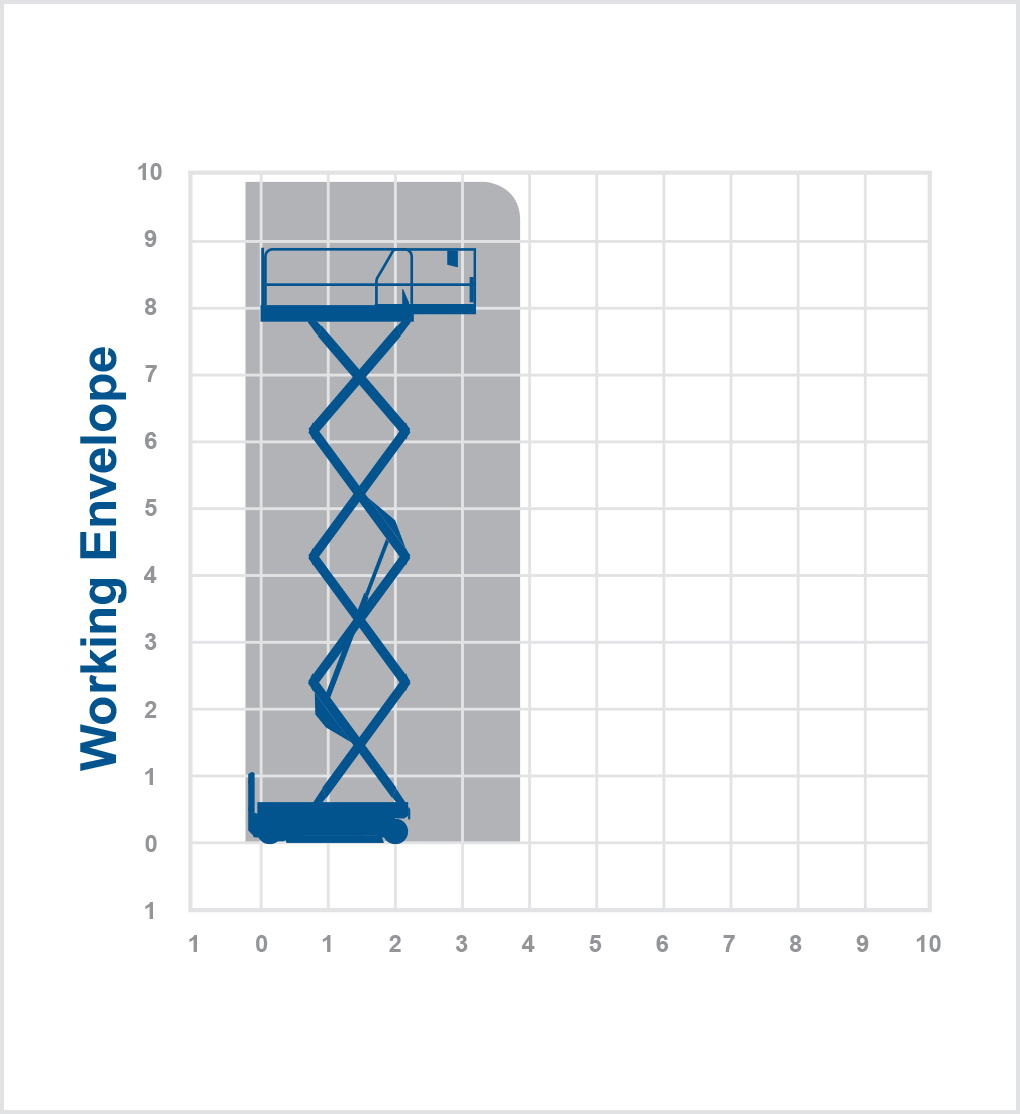

GS26

Working height: 9.75m Safe working load: 454kg Platform/deck size: 2.26m x 0.94m Platform height: 7.9m -

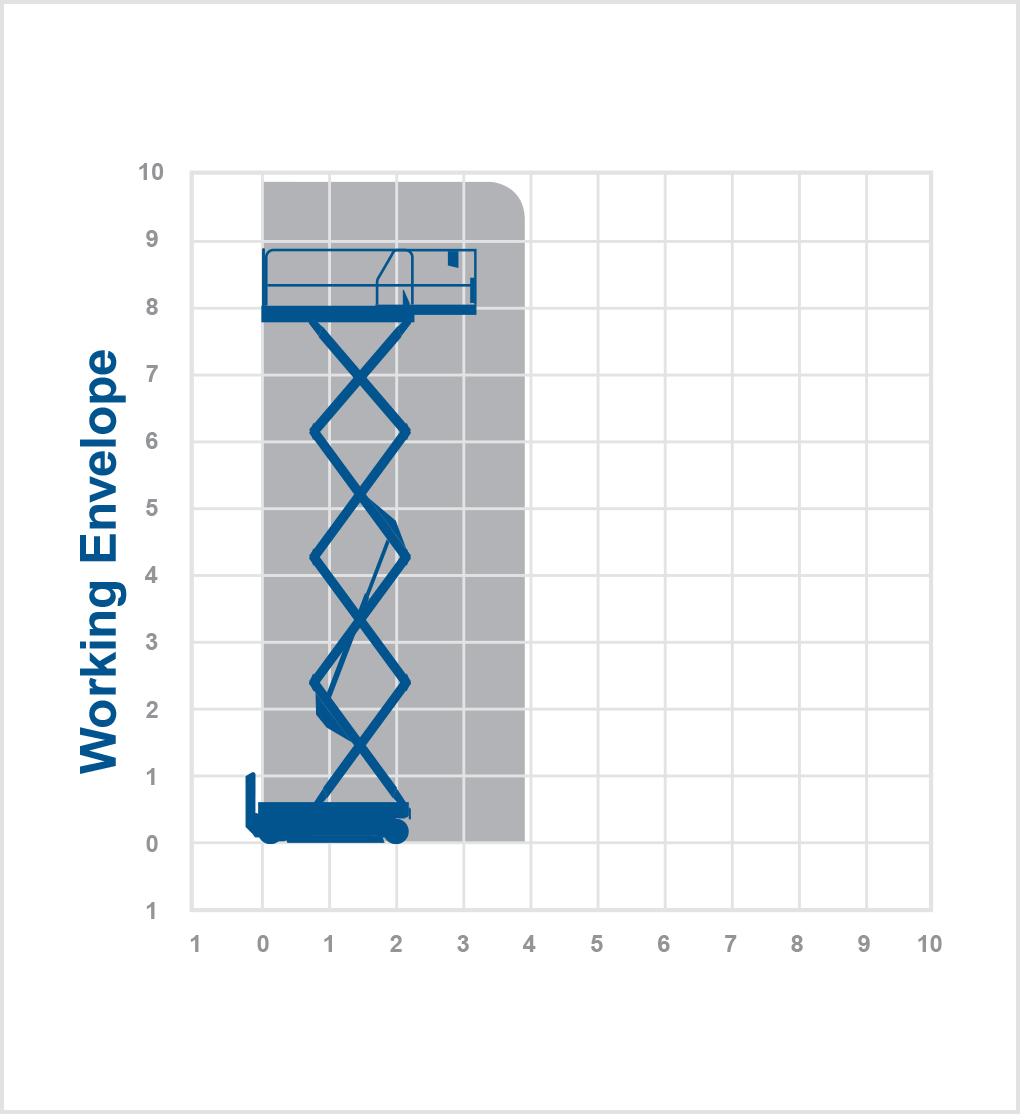

SJ4726

Working height: 9.82m Safe working load: 454kg Platform/deck size: 2.10m x 1.06m Closed width: 1.19m -

GS2669RT

Working height: 9.9m Safe working load: 680kg Platform/deck size: 2.79m x 1.6m Platform height: 7.9m -

4626

Working height: 9.9m Safe working load: 454kg Platform/deck size: 2.11m x 1.07m Platform height: 7.9m -

3226

Working height: 9.92m Safe working load: 227kg Platform/deck size: 2.13m x 0.71m Platform height: 7.92m -

6826D

Working height: 9.92m Safe working load: 567kg Platform/deck size: 2.44m x 1.42m Platform height: 7.92m -

GS2632

Working height: 9.92m Safe working load: 227kg Platform/deck size: 2.26m x 0.81m Platform height: 7.92m -

GS26D-O

Working height: 9.92m Safe working load: 567kg Platform/deck size: 2.51m x 1.55m Platform height: 7.92m -

SJ3226

Working height: 9.92m Safe working load: 227kg Platform/deck size: 0.7m x 2.1m Closed length: 2.33m -

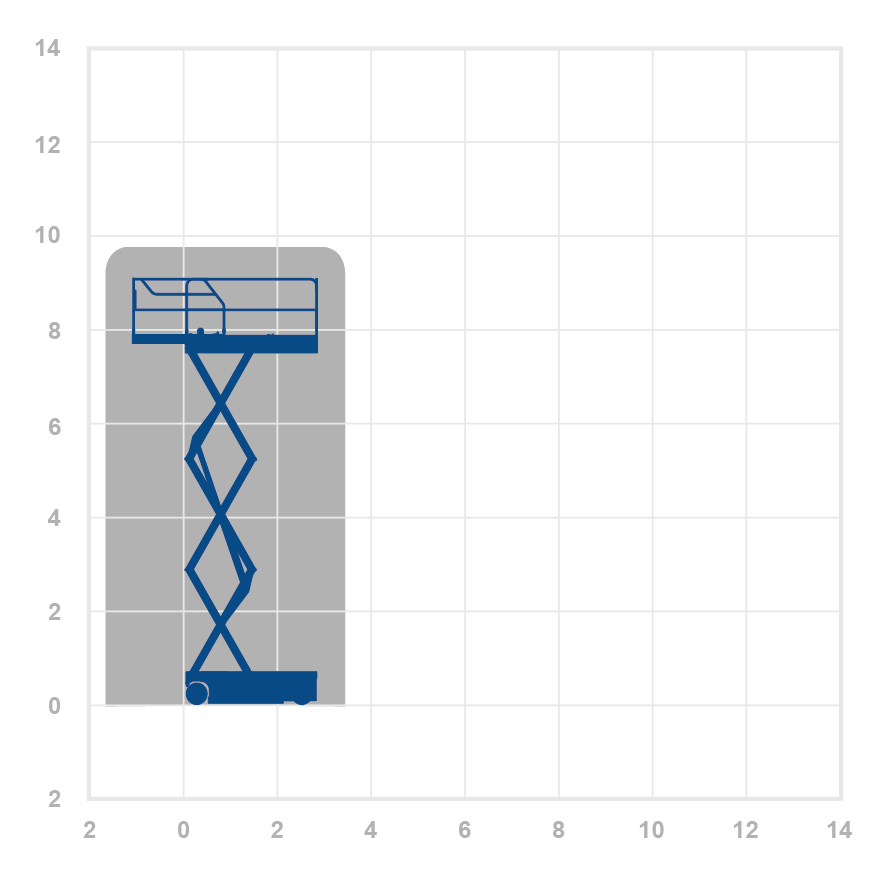

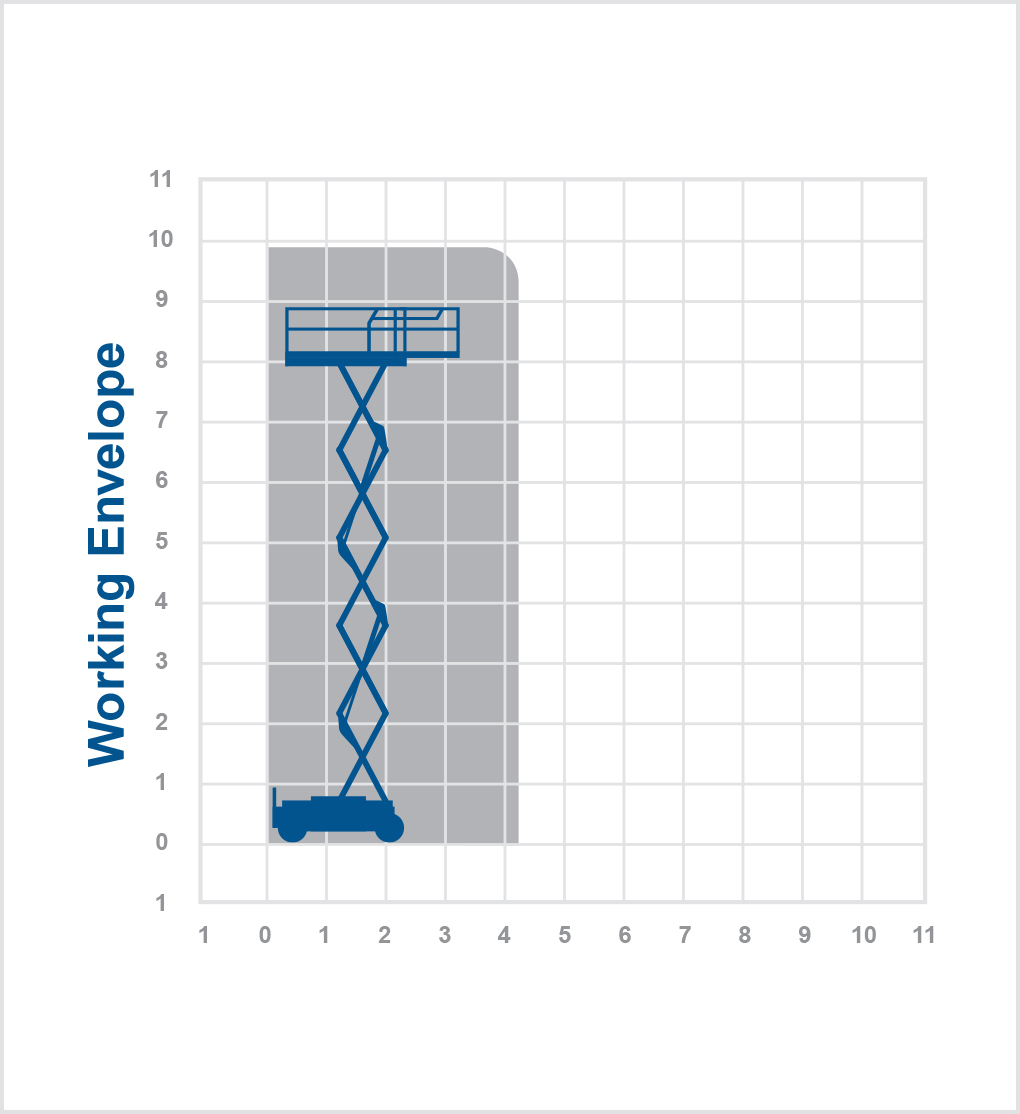

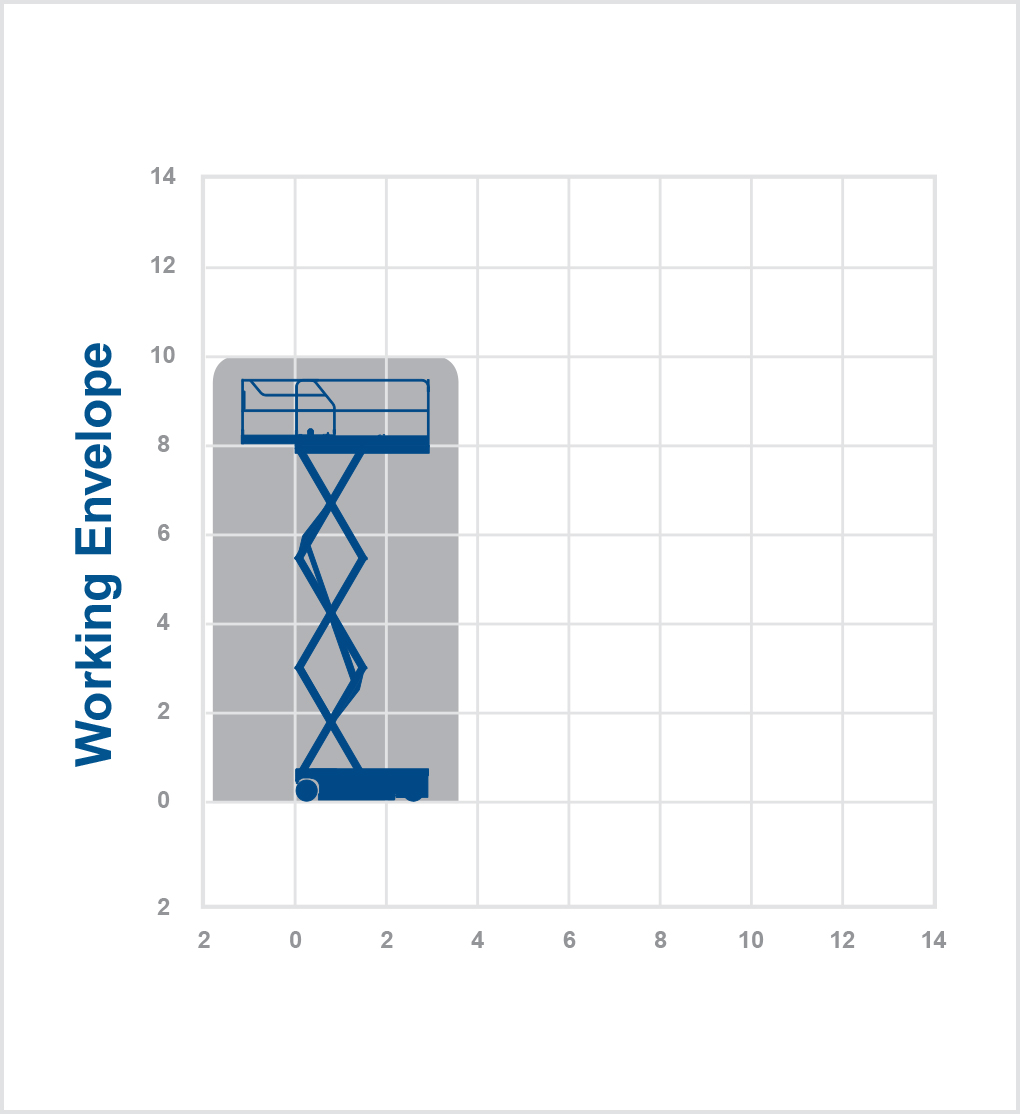

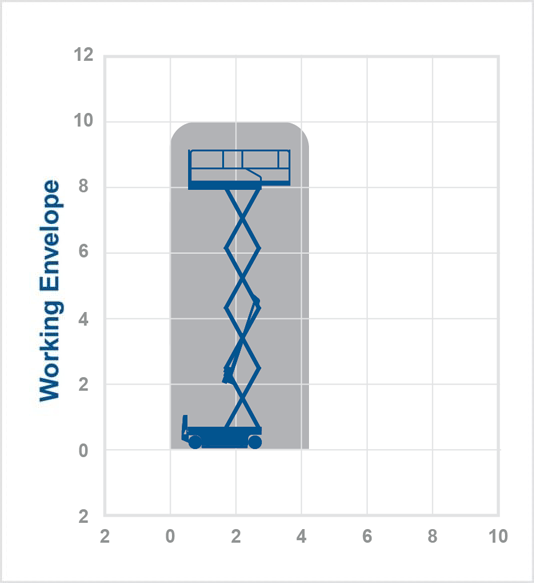

COM10N

Working height: 10m Safe working load: 230kg Platform/deck size: 2.4m x 0.8m Platform height: 8m -

1008AC

Working height: 10m Safe working load: 230kg Platform/deck size: 2.27m x 0.81m Closed width: 0.83m -

1012PA

Working height: 10m Safe working load: 350kg Platform/deck size: 2.27m x 1.12m Closed width: 1.15m -

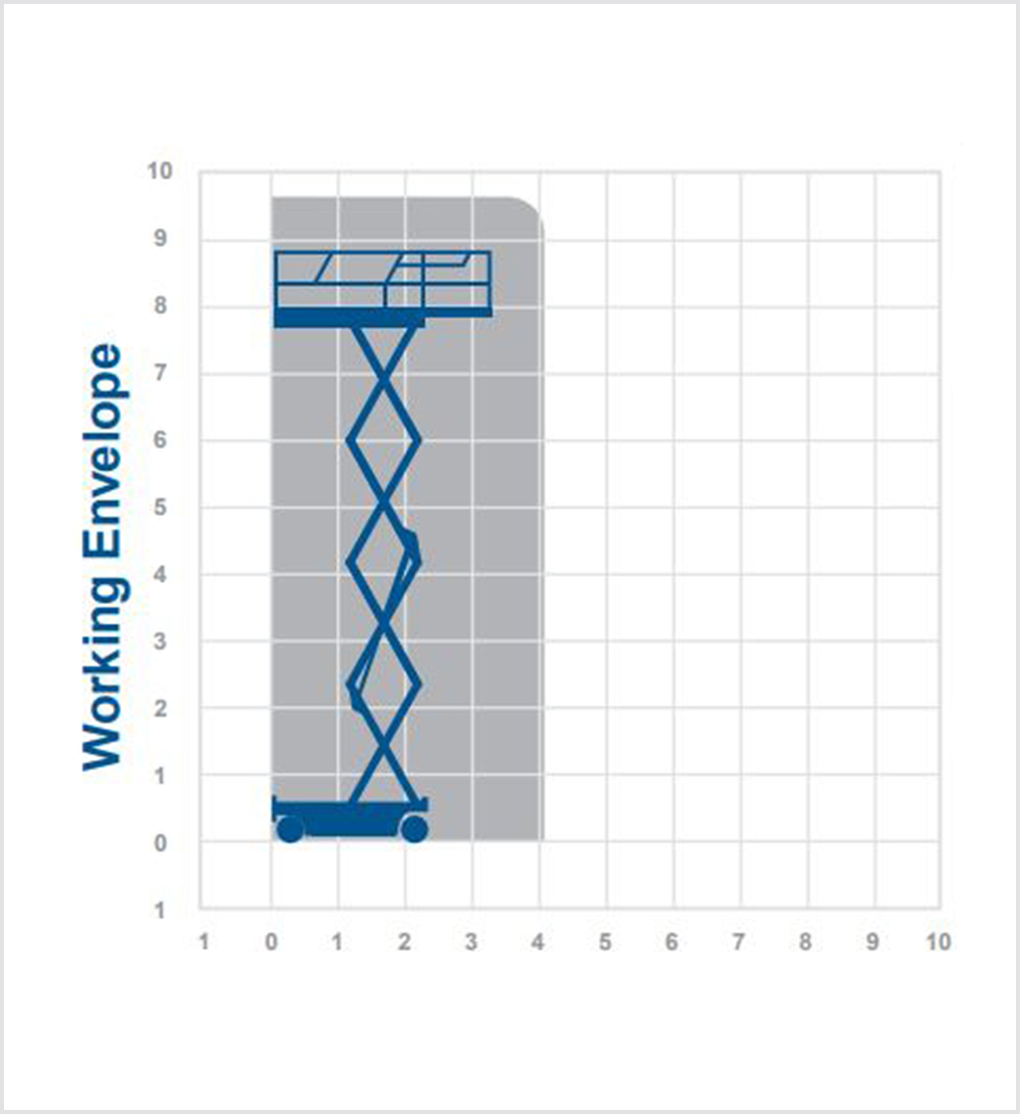

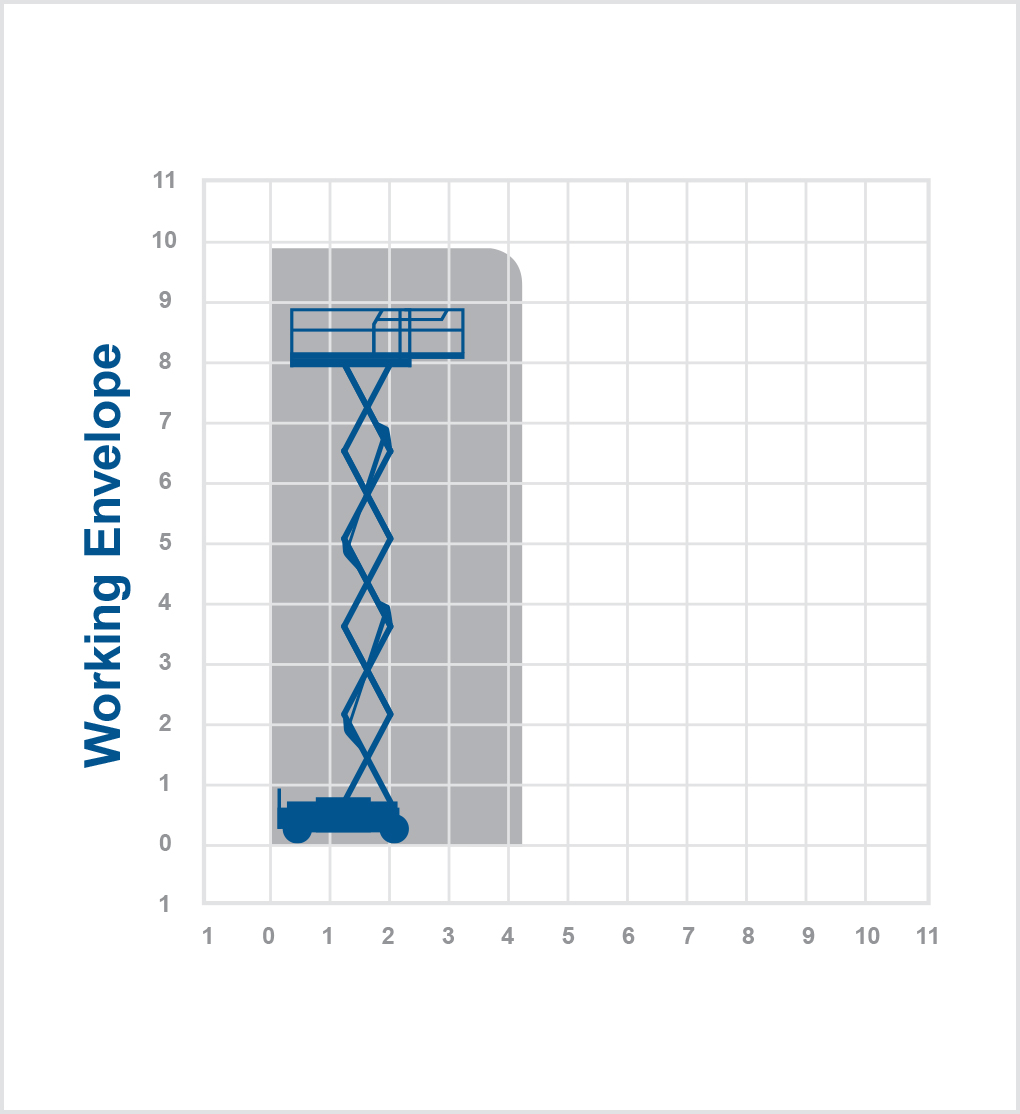

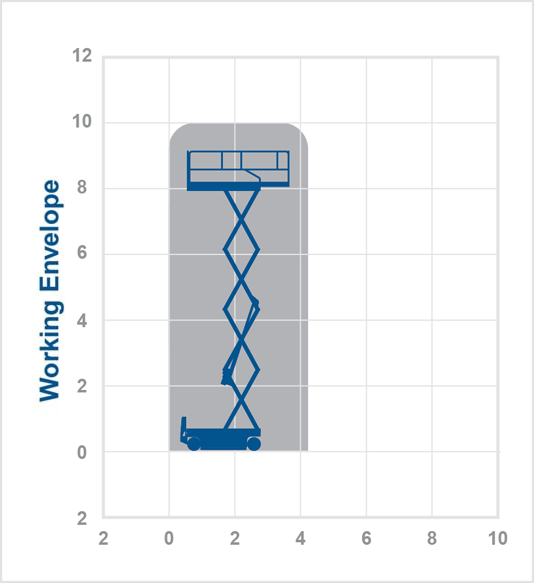

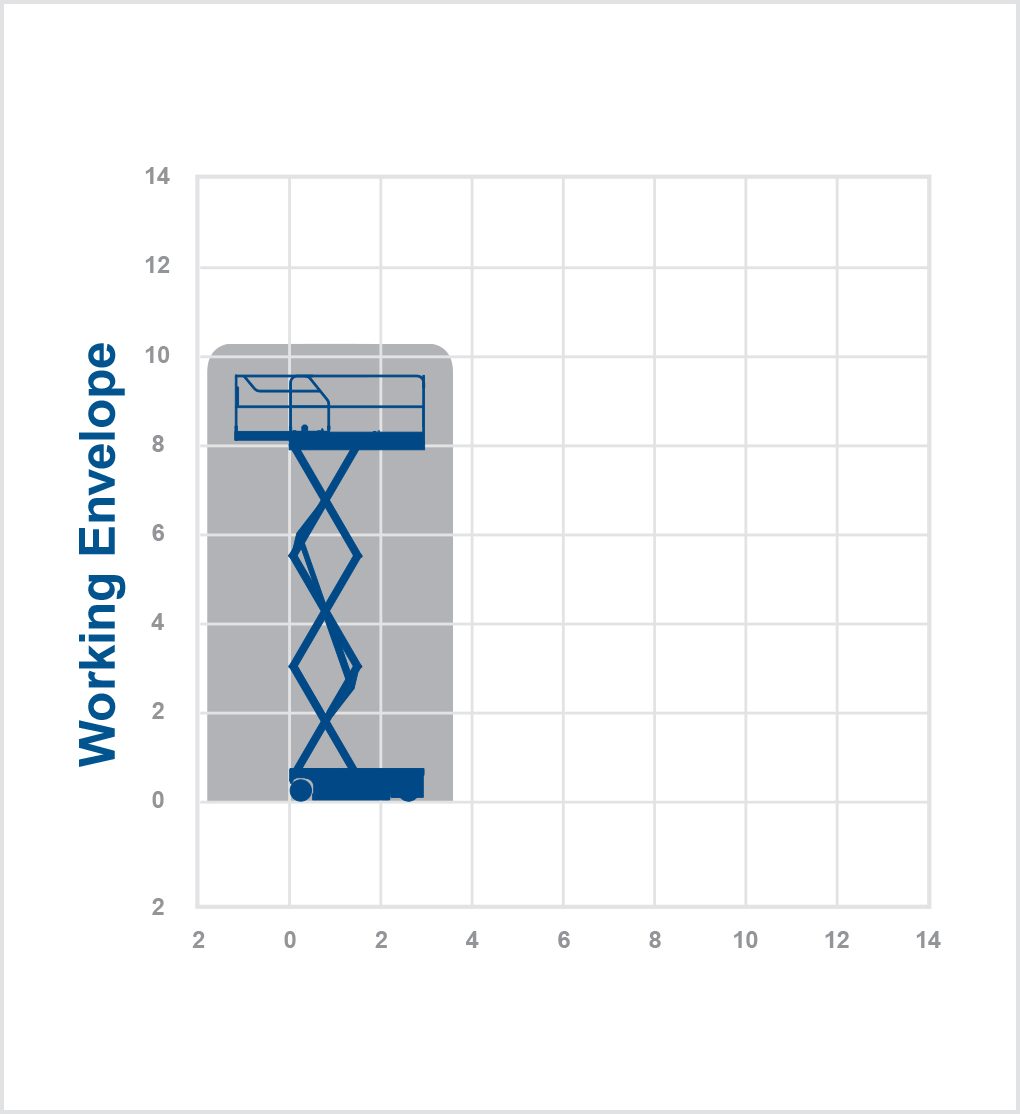

COM10

Working height: 10.15m Safe working load: 450kg Platform/deck size: 2.4m x 1.17m Platform height: 8.15m

loading...